EDGECAM’s Waveform “The Only Way To Successfully Cut For Certain Complex Aerospace Applications”

A cutting tool developer partners with EDGECAM software to ensure its philosophy of taking customers’ machining challenges off their hands, is always successful.

“EDGECAM is a vital part of optimising the process for our customers’ machining issues."Kyocera SGS Precision Tools advises customers, not only on the correct cutting tool for specific applications, but also the best machining strategies to optimise their CNC machine tools.

Tony Theaker, Sales Manager

And for some applications, such as PH stainless steel hydraulic cylinders and a number of aerospace components, Kyocera UK Sales Manager Tony Theaker says the only way to cut them successfully is to use a long end mill and EDGECAM’s game-changing Waveform roughing strategy.

“EDGECAM is a vital part of optimising the process for our customers’ machining issues. Its flexibility means we can employ our cutting tools in the most efficient manner to get the best possible results.”

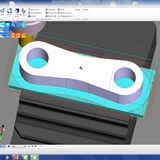

He says the way EDGECAM, from Vero Software, controls the radial engagement of the tool is particularly important. “We can push the tools with high feed and metal removal rates, knowing we’ll get a constant cutting condition. Most CAM software will load up in the corners, causing the tool to possibly fail, so the cutting parameters have to be slowed down. But EDGECAM’s Waveform roughing keeps a constant radial with the cut, so you can push it to the maximum.

“A number of our customers are already using EDGECAM, but we still advise those who aren’t, that the combination of EDGECAM cutting strategies with our cutting tools will optimise their CNC machine tools.”

Technical Manager Barry Ward says: “We take customers’ machining challenges off their hands, and provide solutions by applying all our cutting tool, machine, and software knowledge. This is done through in-house trials, process optimisation, time studies, machining strategy studies, and tool and part design.

“The component may come in from the customer as a model, and our first step typically is to do a time study where we try to optimise what they’re already producing, and give recommendations on tooling. The next stage is where we actually cut the component and try different EDGECAM strategies to come up with the best result. Further trials may be required at the customer, so we’ll take our engineers on-site and support the customer through the whole process.”

He says they also design and implement specialised tooling for specific customers and applications when required, which are tested on the GROB G350 horizontal machining centre at their Tech-Hub in Wokingham.

“Using EDGECAM means we can provide solutions for even the most challenging aerospace components.” He cites the example of a particularly thin component which was fully unsupported. “We worked closely with EDGECAM to produce a bespoke program and developed custom tooling specially for this particular component.”

Aerospace Technologies Manager Ray Gibbs works mainly with large aerospace Tier-1 and Tier-2 companies. “I give them a sequence of tools that we’d recommend to optimise their processes, then we simulate the toolpaths with EDGECAM and show them the cycle times and material removal rates.”

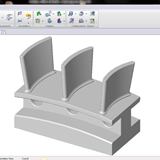

He has created test blocks for producing sample pockets to show customers. “I either carry out a demonstration on-site, or on our own GROB and video the test part being cut and the tools used. Either way, the customers see that the combination of the right cutting tool and EDGECAM strategy optimises their CNC machine tools.

“EDGECAM’s Waveform roughing strategy also improves tool life, particularly when machining Titanium.”

About the Company

Name: Kyocera SGS Precision Tools

Business: Cutting Tool Developer

Benefits Achieved

- Flexibility.

- Can employ cutting tools in the most efficient manner.

- Can push tools to the maximum without it failing.

- Can provide solutions for even the most challenging Aerospace components.

- Improved tool life.

- Improved material removal rates.

- Quicker cycle times.

Comments

“Consumable costs are also reduced as the Waveform strategy means the end mill has worn down evenly, rather than being damaged because of any overloading in the corners.”

Jose Ucar, EU Marketing Manager